About Zero Thermal

Our History

Zero Thermal™ polymers are the outstanding result of 33 years of cumulative research, career, and experience of Marcos González, Ph.D. in the medical and pharmaceutical manufacturing industry, along with an extensive history of achievements in presenting new technologies and fabrication methods.

The base of Zero Thermal™ technology is the bio-mineralization process found in nature, responsible for the formation of minerals or composites.

Marcos has worked with scientific, pharmaceutical, and medical industry world leaders, developing remarkable relationships by participating in University volunteering services, medical centers, and government agencies, with significant input in new therapy research for kidney, heart, and hepatic diseases.

In Marco’s own words, Zero Thermal™ “is more of a technological discovery than an invention”.

Zero Thermal™ (ZT) is an organic polymer and technology derived from extracts of brown seaweeds, red and green algae that are mainly polysaccharides, phlorotannin’s, proteins, and nucleic acids. Polymers show various biological activities in both plant and animal systems and are involved in host defense mechanisms. There is interest in agriculture in polymers that elicit defensive responses resulting in protection against pathogens or insect damage. Pathogen suppression can also occur with a high degree of confidence through indirect inhibition. By converting the iron in soil into a chelating agent that manipulates the iron so that it becomes unavailable to pathogenic fungi and allows certain native bacteria that have a positive effect on plant growth to grow under iron-limiting conditions.

Having more than 135 proven applications, it is fair to say that almost every existing industry can benefit from Zero Thermal™ biopolymers in their unique way. Ranging from Agricultural to Oil & Gas remediation, heat-coating of crops and fruits before and after harvest to the betterment and hardening of a diamond tip oil drill.

Algae Polymers: Molecular Biomineralization Technology

Molecular Biomineralization (MBM) is the process of mineralizing organic molecules and matrices. This process has numerous applications in the life sciences, including developing drugs and producing new minerals. Moreover, it plays a crucial role in the processes resulting in the formation of crystalline materials.

Biomineralization is an example of nature’s amazing ability to create materials from simple compounds. A spectacular example of biomineralization is the intricately structured cell walls of diatoms. Diatoms are unicellular algae that create silica enclosures surrounding the cytoplasm. These symmetrical “glass house” cell walls are intricately decorated with pores, ridges, slits, and other nanoscale patterns in the silica. The cell walls of diatoms are among the best examples of this process. Diatom cell walls are made of amorphous, hydrated silica and are highly regular in structure. Diatoms are photosynthetic organisms that manufacture their own food, much like plants. Phytoplankton is a type of algae important for maintaining ocean oxygen. They join the multitude of organisms that float on the water’s surface. The nanotechnology industry is trying to duplicate the diatom´s symmetrical “glass house” cell wall patterns during nanofabrication procedures to produce a variety of useful nanoscale structures, including sensors, drug delivery systems, and advanced coatings for the aerial and aquatic craft.

Focusing on the formation, organization, and mineralization processes of new structural materials. The topic of biomineralization spans a range of diverse disciplines, including molecular biology, supramolecular chemistry, materials science, and engineering. These complex biomineral structures reveal our limited understanding of a fundamental biological question of how a cell translates linear DNA sequence information into modeled three-dimensional structures. Important lessons will be learned from diatoms regarding the mechanism of action by which eukaryotic cells assemble their cellular machinery to execute a genetically encoded morphogenetic program.

Algae Molecular Biomineralization Technology

Algae Polymers are a new and exciting discovery in biomineralization developed from algae. Algae are composed of mostly polysaccharides, phlorotannin, proteins and nucleic acids. Algae Polymers are used in many industrial processes. They include soil and water remediation, agriculture, aquaculture, poultry, aquaculture, poultry, mining, petroleum, and water based ecological protective coatings. Using algae-based polymers is an environmentally friendly and cost-effective way to produce polymers for petroleum and oil applications.

Zero Thermal Facts

- A truly revolutionary discovery in biomineralization.

- Developed from algae.

- Cryptobiotic viscoelastomeric elastomeric polymer.

- The elastomeric polymer has multiple technical and organic advantages.

- Considered a nanotechnology polymer.

- Can be used as an advanced additive for the industry.

- Patented and registered in the United States.

- Technology is protected with five unpublished protected trade secrets.

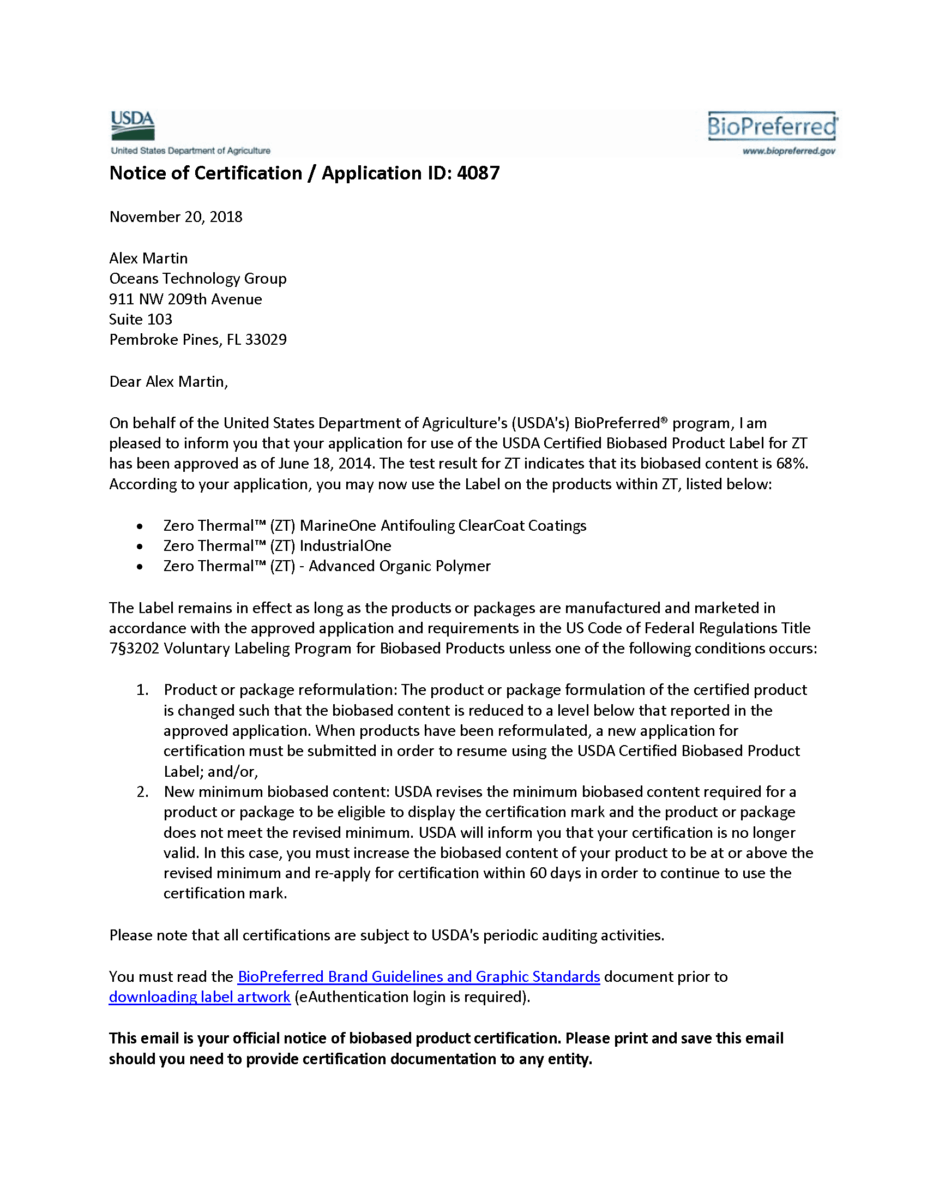

- USDA Biobased Certified 68% Organic.

Zero Thermal technology is USDA certified as a 100% bio-compatible polymer. There is a fully sustainable and independent manufacturing process by the inventor Marcos Gonzalez in the United States.

Marcos Gonzalez holds a Ph.D. in Molecular Biology and has a strong background with over 33 years of experience manufacturing medical devices and pharmaceutical products. Marcos has a proven track record of progress in developing and deploying new technologies and manufacturing methods. This is demonstrated through the numerous registered U.S. patents The range of its various patent filings includes medical sciences, agriculture, water treatment and remediation, and polymers used in industrial applications of material sciences. Its patented Zero Thermal polymers have been used in applications for the remediation of worldwide environmental events in the oil and mining communities.

Marcos has worked with industry leaders in the scientific, pharmaceutical, and medical device communities. He has developed excellent relationships within the medical industry by participating in numerous volunteer service hours at universities, medical care centers, and government agencies. His involvement includes the investigation of new therapies for treatment in the areas of renal, cardiovascular, and liver disease.

Marcos has numerous partnerships worldwide with universities in developing and presenting medical devices and pharmaceutical drug delivery systems. At the University of Miami, he currently manages and participates in clinical trials focused on using his proprietary medical innovations with cell culture and stem cells.

Marcos has the capability to perform research and development in the area of FDA product submissions. It owns and operates a registered, regulatory-compliant facility with the ability to perform photo tests for research and development and a full pilot scale capability to manufacture regulatory-compliant validation batches. This facility also facilitates the manufacture of proprietary molecular formulations that are distributed and sold worldwide.

As an industry leader in the control and spread of infectious disease pathogens, his work with the University of Miami has ranged from projects to control the spread of American Trypanosomiasis disease, as well as the Black Sigatoka Virus responsible for infecting agricultural industries. He has also had numerous meetings with organizations in the mining communities of South America that prevent the spread of neurological impacts to humans with the development of mining technologies and reagents that demonstrate a lower incidence of toxicity. Their most recent introduction of a new technology that provides solutions to the COVID-19 virus has been the development of aseptic coatings capable of sequestering and preventing the spread of SARS-COV-2 strains with human physical interactions on hard surfaces.